In a commercial kitchen, the cooler runs quietly in the background. But when it’s disorganized, the risks are anything but quiet. Just one misplaced pan of raw chicken above ready-to-eat produce can trigger a chain reaction: cross-contamination, spoiled inventory, a failed health inspection, or worse, a foodborne illness outbreak.

In the eyes of a health inspector, shelf placement is as critical as handwashing. That’s why having the proper walk-in organization isn’t a nice-to-have. It’s a non-negotiable.

The Shelf Mistake That Could Cost Thousands

Walk-in coolers aren’t just storage. They’re an extension of a foodservice operation’s food safety plan. When they’re structured correctly, they protect product, reduce loss, and help avoid costly violations. When they’re not, they create hidden risks that often go unnoticed until an inspection or incident.

Poor organization can lead to raw proteins dripping onto produce, hot spots that accelerate spoilage, or blocked airflow that causes temperature swings. Inspectors often cite these issues because they point to bigger operational breakdowns. Even experienced staff can make mistakes without clear shelving rules.

Well-defined shelf placement, based on risk level and cooking temperatures, is a simple yet essential step that enforces food safety. Inspectors look for it immediately. A cooler that’s clean but improperly organized still raises red flags.

What Goes Where? Shelf Placement That Works

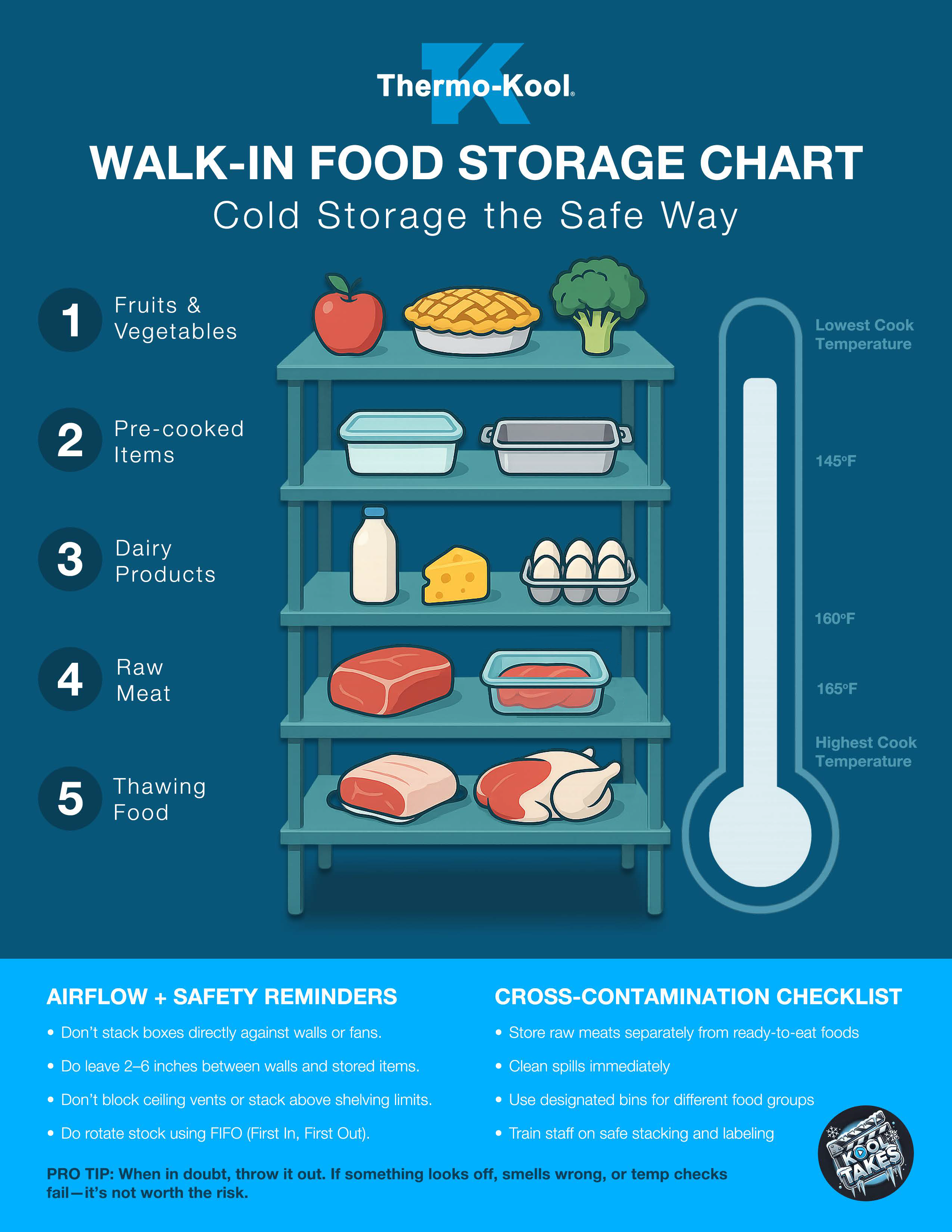

Ready-to-eat foods should always be on the highest shelves to prevent drips or exposure to raw ingredients. This includes packaged sandwiches, shredded cheese, and bottled dressings.

Middle shelving should be reserved for washed produce and cooked foods. These items have already gone through prep or cooking steps and carry less risk than raw proteins but more risk than sealed, ready-to-serve products.

Staff should utilize the lowest shelves for raw animal proteins, organized by their required internal cooking temperatures. Beef and pork should sit above ground meats, which should sit above poultry or seafood. This sequence protects the more vulnerable items and keeps contamination risk as low as possible.

No food should ever be stored directly on the floor. This area needs to remain clear, except for clean trays, spill pans, or designated empty containers. Boxes placed directly on cooler floors signal a violation and make it easier for bacteria to spread.

Airflow and Cleanliness Are Part of Shelf Strategy

Shelf placement doesn’t just affect food safety; it also impacts cooler performance. Packed shelving, oversized containers, or a lack of spacing between products can block airflow and strain refrigeration systems. Over time, this leads to temperature fluctuation, product spoilage, and equipment wear.

Wire racks allow better circulation than solid shelving. Every item should have space around it to help maintain an even temperature. Avoid stacking too tightly or blocking evaporator fans, especially during high-volume prep periods.

Another critical factor is routine cleaning. The shelves, walls, and floors should be cleaned regularly. Rusted racks, broken supports, or any surface that can’t be fully sanitized should be replaced. These aren’t just signs of wear but also potential liabilities during a health inspection.

Mistakes That Lead to Bigger Problems

Operators often find out too late that their walk-in layout caused the problem. Storing raw seafood above prepped greens, overloading shelves before service, or ignoring small leaks and spills can add up quickly. Even something as simple as using a container that sticks out too far can block airflow or knock other items out of place.

One of the most common and avoidable issues is allowing boxes or bins to sit directly on the cooler floor. That single oversight is a health code violation in most states and creates an unnecessary food safety risk.

Design matters here. A walk-in built with food safety in mind can reduce the burden on staff and help reinforce the right behaviors.

Create even more profits by installing Bluezone in your commercial walk-in: